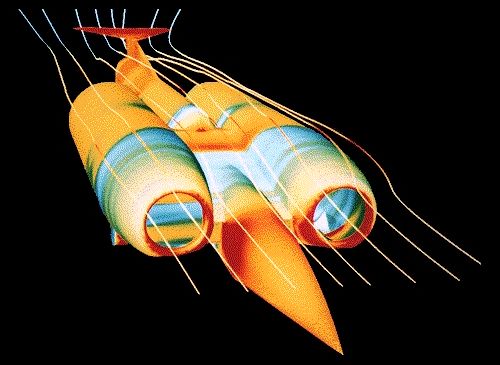

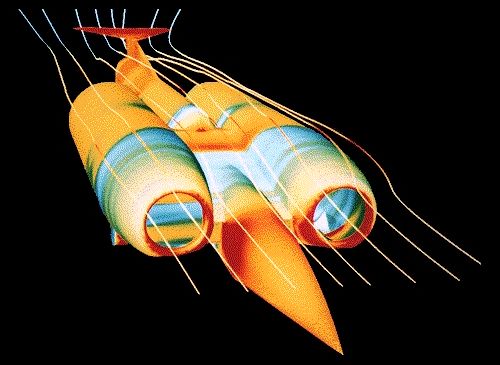

Gaining access to a Cray Research 92 computer with Flite aviation design

software enabled them to refine the concept, using computational fluid

dynamics. After

a great deal of work, they were able to predict the car's performance

under a variety of conditions.

Gaining access to a Cray Research 92 computer with Flite aviation design

software enabled them to refine the concept, using computational fluid

dynamics. After

a great deal of work, they were able to predict the car's performance

under a variety of conditions.

The concept looked promising, but the team wanted to be absolutely

certain that they were taking the correct approach. An accurate, 1/25th-scale

model

was built, and run on a military rocket sled track at Pendine Sands in

South Wales, where it was mounted in front of a rocket and run at

supersonic

speeds. After each pass it was lowered, until at the end it skimmed

across the surface of the track. Data collected from these tests enabled

the team to become

the first to fully understand what really happens to the air underneath a

car when it goes faster than the speed of sound.

Another breakthrough followed. The data from the computer projections

and the supersonic scale model testing were then compared. To the

amazement of everyone

involved, the conclusions from both testing methods correlated almost

exactly.

Noble wisely decided that since this was to be an exceptional race car,

its driver must have some exceptional skills. And the more the project

progressed, the

more it became apparent that he needed to focus on its other aspects:

Noble wisely decided that since this was to be an exceptional race car,

its driver must have some exceptional skills. And the more the project

progressed, the

more it became apparent that he needed to focus on its other aspects:

"My situation is that I have made a very, very painful decision not to

drive. We're in a situation where, to get the car operational by next

year, we've got to

go for one hell of a build operation. Basically, to fund that and to

manage that is going to be a tremendous undertaking. The reality is that

we've got to find

somebody who has got to live with the team, who has got to actually

train up with the team, and who will then become the car's driver."

A competitive selection process took place to see who would drive the

fastest car ever built. But rather than advertise for people to apply,

he simply allowed

the message to spread, thereby providing the applicants with their first

test — their own initiative.

Thirty people applied. All of them were either drag racers or pilots. At

the Center of Human Sciences in Farnborough, Professor Roger Green

provided help with

the project:

"What we had to do was decide how to whittle this down further. The most

obvious thing to do was to give them all a sanity test and take the

ones who failed.

But one Richard Noble is obviously quite enough already."

The ability to be part of a team was given equal importance as being

able to control the race car. Based on their experience, the thirty were

first narrowed

down to sixteen, who were given numerous intelligence and personality

tests. The goal was to find the most analytical individuals, who would

be likely to

contribute the most in solving problems, both in controlling ThrustSSC,

and in its design.

Eight remained, all of whom were pilots. The next objective was to find

out who could handle extreme stress and discomfort for extended periods,

and yet still

be part of a team that was working toward a common goal.

For most of two days and both nights, the eight were kept at the Center

of Human Sciences. The Thrust team was to spend a great deal of time

working for long

hours on a hot desert. As a surprise, they were kept awake all night in a

heat chamber, where they were filmed at all times and given difficult

computer-based

tests at periodic intervals, to see how fatigue and stress affected

their performance.

British rally champion Russell Brooks gave the five potential drivers

that remained the opportunity to drive a Formula Two rally car in time

trials as quickly

as their abilities allowed. Feedback from Brooks narrowed the five down

to four, who then interacted with the rest of the team, facing design

challenges.

Finally, without the four realizing it, the members of the team filled

out questionnaires asking their opinions.

Of all of the contenders, one man came out on top: a British Royal Air Force jet fighter pilot named Andy Green.

Of all of the contenders, one man came out on top: a British Royal Air Force jet fighter pilot named Andy Green.

But once the car had been designed, and the driver and race track

selected, the logistics in the project that remained were staggering.

There was the cost of

building the car, testing it, bringing it from England to the desert in

Nevada and back, and looking after a substantial support crew. Richard

knew that in

order for this to happen, he would need a lot of help from a lot of

talented and dedicated people working together. The more the concept of

Noble, Ayers,

Bowsher, Green and the rest of the team was refined, the more it seemed

that the most significant obstacle to overcome was in raising the

enormous amount of

money it would take.

Robin Richardson suggested forming the Mach 1 Club, which provided a way

for land speed record racing enthusiasts to become involved in

everything from

publicity to fundraising through the sale of memberships and souvenirs.

Early on, Castrol and Dunlop had become sponsors of the ThrustSSC

project. This was a big help, but it would take far more. In the hope of

securing the

sponsorship that would make it possible to race the car, Noble took his

vision to a number of large corporations, explaining what he was going

to do, and what

it would mean to the United Kingdom and to the automotive industry.

People listened, but none stepped up with a commitment to provide all

that was needed. He

continued knocking on corporate doors. "Quite impressive, Mr. Noble.

Call us when you've done it."

This was in the mid-1990s, a time when the Internet was new to most of the world. And there was the answer.

In April of 1995, team member Robin Richardson obtained help from his

employer, Digital, in launching a Web site for the ThrustSSC project. In

November of

1995, Nick Chapman and Jeremy Davey took on the responsibility of

managing the site. In essence, the message was that ThrustSSC was being

built, and it was

going to be the fastest car in history. It was also going to be the

first car to officially break the sound barrier. But considerable help

was needed to make

it all happen. The necessary technology, equipment, and projected costs

were outlined.

Arrangements were made to borrow the largest airplane in the world, the

Russian Antonov 124 cargo plane. The Antonov would make it possible to

transport the

completed race car, its spare jet engines, spare parts, tools, pit

control station, computers and data acquisition equipment, all of the

required support cars,

trucks, trailers, and ATVs, ultralight aircraft for flying overhead to

check the track and take photographs, a number of big tents to protect

everything, and a

whole lot of fuel.

Arrangements were made to borrow the largest airplane in the world, the

Russian Antonov 124 cargo plane. The Antonov would make it possible to

transport the

completed race car, its spare jet engines, spare parts, tools, pit

control station, computers and data acquisition equipment, all of the

required support cars,

trucks, trailers, and ATVs, ultralight aircraft for flying overhead to

check the track and take photographs, a number of big tents to protect

everything, and a

whole lot of fuel.

On the Web site, mention was made that in order to do all of this, it

would take a total of 250,000 gallons of fuel. If no single source was

going to provide

it, would some of you care to help by buying 25 gallons?

British television and radio picked up the story. Traffic to the site

began to grow. All through the United Kingdom, a sense of duty and pride

led to everyone

from executives to young children sending in payments for 25 gallons, a

hundred gallons — whatever they were able to share.

Not only was history made by building and racing the ThrustSSC

successfully, but their Web site demonstrated the potential of the

Internet as a means of

sharing a story with the world, and for helping to create the interest

and support in a project that ultimately made it possible for the team

to meet a goal

that relatively few believed would ever be possible.

Special thanks go to Jeremy Davey, the Webmaster of the ThrustSSC Web

site, who took most of the pictures that appear in this article. Until

the team reached

their objective, their site was revised regularly. Jeremy Davey did a

superb job of sharing the excitement and suspense of their adventure

with the rest of the

world.

Special thanks go to Jeremy Davey, the Webmaster of the ThrustSSC Web

site, who took most of the pictures that appear in this article. Until

the team reached

their objective, their site was revised regularly. Jeremy Davey did a

superb job of sharing the excitement and suspense of their adventure

with the rest of the

world.

The ThrustSSC Web site can be found at

http://www.thrustssc.com/

A souvenir CD-ROM made up of the entire ThrustSSC site is available. It

contains the entire story, including lots of engineering information, a

number of audio

and video clips, and thousands of photographs. Proceeds from the sale of

the CD-ROM and from other souvenirs go towards paying back loans that

were made to the

team for this extremely expensive endeavor.

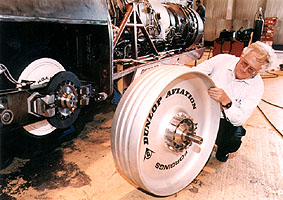

Shown on the right are world land speed record holder Richard Noble

(left) and aerodynamicist Ron Ayers (right), standing beside ThrustSSC

as its construction

was underway.

Shown on the right are world land speed record holder Richard Noble

(left) and aerodynamicist Ron Ayers (right), standing beside ThrustSSC

as its construction

was underway.

In an article written by Andrew Graves, published in the January 1998

issue of Prototyping Technology, Ayers explained his role in the

project.

"The rocket sled tests confirmed our computer predictions. At that

stage, my job as an aerodynamicist was substantially done. The shape was

defined."

"I became more involved again when the car was running. This was because

I then had to specify what its performance capabilities were and define

the run

profiles for each run and effectively define each run as a scientific

experiment. A run profile includes the rate of acceleration and at what

level the car

reaches certain speeds."

"The third member of our design team is a chap called Jeremy Bliss, who

used to do active suspension on Formula 1 in the days when it was

allowed."

"Experiments included exercising the active suspension by pushing it up

and down, partly to test it, but also to check the aerodynamic

characteristics of the

car during a range of circumstances."

"There were over 120 sensors on the car measuring everything you can

think of, from the wheel loads to the bearing temperatures, the brake

temperatures, the

aerodynamic pressures on thirty different points, hydraulic pressures,

engine characteristics and fuel forces. So we treated it like a first

prototype

airplane, going a little faster each time and checking the data."

"We could download the data between runs and check the safety-critical

items like the wheel loads on the desert, the bearing temperatures, et

cetera. We did

this between runs, even when we were breaking records and we had to do

the turnaround within the hour. While we were refueling the car, which

took about twenty

minutes, we could download data that myself, Glynne Bowsher, Jeremy

Bliss and probably Andy Green, the driver, would then check. We knew in

advance what we

wanted to check. We could call up that data and check that the lines

were where we expected them to be on the graphs, and that there was

nothing near to the

limits. If this was so, then we would authorize the next run."

"We could download the data between runs and check the safety-critical

items like the wheel loads on the desert, the bearing temperatures, et

cetera. We did

this between runs, even when we were breaking records and we had to do

the turnaround within the hour. While we were refueling the car, which

took about twenty

minutes, we could download data that myself, Glynne Bowsher, Jeremy

Bliss and probably Andy Green, the driver, would then check. We knew in

advance what we

wanted to check. We could call up that data and check that the lines

were where we expected them to be on the graphs, and that there was

nothing near to the

limits. If this was so, then we would authorize the next run."

In an interview published on the ThrustSSC Web site, former missile designer Ayers provided these cheerful thoughts:

"If the front of the car lifts by as little as one degree, or even half a

degree, all the weight will come off the front wheels. The car will

then nose up and

flip over backwards. The forces acting upon it at maximum speed will be

in excess of forty times the force of gravity."

"If the nose comes up, you're going flying. But equally, if it goes

down, then you're going mining. The car's aerodynamic behavior has got

to be

neutral."

Jeremy Bliss designed an active rear suspension system to allow the rake

of the car to be adjusted during its runs, very quickly. It worked

quite well.

Jeremy Bliss designed an active rear suspension system to allow the rake

of the car to be adjusted during its runs, very quickly. It worked

quite well.

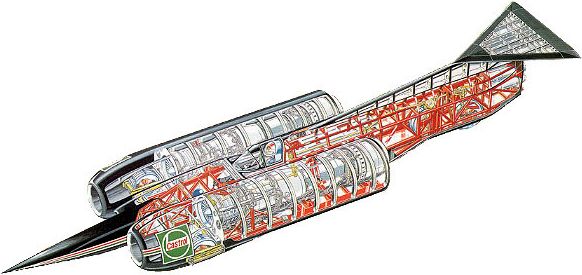

ThrustSSC is fifty-four feet long, and twelve feet wide. It is powered

by a pair of Rolls-Royce Spey 202 jet engines from a Phantom fighter

producing 50,000

pounds of thrust and 110,000 horsepower. Easily as awesome as any car

ever built, ThrustSSC is an incredible achievement and an overwhelming

sight.

Some think the car looks like a giant hot dog. An article Ayers wrote about the shape of the car contains a story worth sharing:

Some think the car looks like a giant hot dog. An article Ayers wrote about the shape of the car contains a story worth sharing:

"The shape of the car has certainly aroused much comment. Everyone

agrees it is impressive. Many people have said it is beautiful. One

young lady disagreed.

She told me in accusing tones that the shape I had designed was the

ultimate male sex symbol. Lamely, I shrank from asking her what

geometric modifications

would be required to turn it into a female sex symbol. I contented

myself by telling her that the shape had been designed by mathematics,

and that I would

check the equations to see which one contained the gender information."

After its construction, the car was taken to a 7,000-foot airfield in

Farnborough, where low-speed tests verified that all systems performed

as

intended.

Then another longtime racing fan became involved. King Hussein of Jordan

provided access to a large area of the Jafr desert, with the full

cooperation of the

Jordanian Army. On two visits a number of test runs were made. The team

spent thousands of hours clearing a course for the car to run on,

battling dust storms

and torrential rain.

Then another longtime racing fan became involved. King Hussein of Jordan

provided access to a large area of the Jafr desert, with the full

cooperation of the

Jordanian Army. On two visits a number of test runs were made. The team

spent thousands of hours clearing a course for the car to run on,

battling dust storms

and torrential rain.

Back in the UK, Aireshelta flew in a huge inflatable shelter to house

the race car. The desert surface ultimately proved to be too uneven for

the car to go

beyond 540 miles per hour, and a rear suspension bracket was damaged.

Nonetheless, ThrustSSC essentially performed very well, and was found to

be stable and

safe.

With just a few weeks remaining before the team's scheduled departure to

Black Rock, further refinements and minor repairs were carried out. At

this point, now

that people could see that the team had a very real chance of success,

more sponsors became involved, and new equipment was added. For the

first time since the

team had begun their adventure, there was no doubt that the trip to

Black Rock was going to proceed according to plan.

After the final adjustments and improvements were made to the car,

ThrustSSC was pronounced ready for its mission. It was time to make

history.

After the final adjustments and improvements were made to the car,

ThrustSSC was pronounced ready for its mission. It was time to make

history.

Craig Breedlove and the Spirit of America race team were already at

Black Rock, preparing for their own assault on the land speed record,

and the sound

barrier.

Everything that was needed, totaling almost ninety tons, was loaded into

the Antonov cargo plane and flown to Gander, Newfoundland for a fuel

stop, and then on

to Reno, Nevada.

After the flight, the crew, the race car, and all of the team's equipment were transported to the Black Rock Desert.

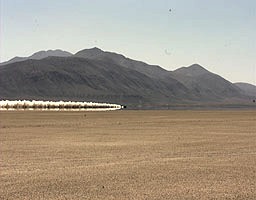

Six miles of the desert were used to bring the car up to the timing

lights set a few hundred feet apart. Then comes the measured mile, where

the speed of the

car is recorded. Another six miles were used to bring the car to a stop.

To mark the race course, a mixture of gypsum and water was used to create perfectly straight lines twelve miles long.

The desert has been used as a firing range, and is littered with

thousands of artillery shells. The entire course had to be inspected and

cleared of anything

that might cause damage to the race car's engines or wheels.

The desert has been used as a firing range, and is littered with

thousands of artillery shells. The entire course had to be inspected and

cleared of anything

that might cause damage to the race car's engines or wheels.

In early September of 1997, the stage was finally set for the ultimate

car race — to be the first to officially break the sound barrier in a

race

car.

Between setting up their equipment, preparing the race course,

mechanical challenges involved in taking care of the race car and

continuing to refine it, press

conferences, documenting everything, and waiting for the Spirit of

America to make runs, the team spent over two months on the desert.

Andy Green rather casually went about his mission of driving ThrustSSC.

Andy's skills as a British Royal Air Force pilot were put to good use.

On September 25th of 1997, the ThrustSSC team reached one of

their goals by setting a new World Land Speed Record, with a two-way

average speed of

714.144 miles per hour.

The new record was below the speed of sound, but it nonetheless clearly

proved the project worthwhile. The team had designed, built and raced

the fastest car

in history.

A few days later, an unofficial burst up to 750 miles per hour proved

that the car could go supersonic and remain controllable. The design

ideas of Ron Ayers,

Glynne Bowsher, Jeremy Bliss and rest of the team, along with Richard

Noble's perseverance, and Andy Green's talent and experience had once

again proven

themselves.

Then, on Monday, October 13th, Andy and the ThrustSSC team shocked the world with two runs, at 764.168 miles per hour (Mach 1.007) and 760.135 miles

per hour (Mach 1.003).

|

It has been said that the first car race probably took place the first

time two cars pulled up beside each other. And ever since then, there

has been

competition to see who could go the fastest.

It has been said that the first car race probably took place the first

time two cars pulled up beside each other. And ever since then, there

has been

competition to see who could go the fastest. On September 4th, 1997, Breedlove and the Spirit of America

crew began testing the car at Black Rock. Breedlove and his team

struggled with

everything from a damaged engine (and a spare engine back in California

that they hadn't even brought with them) to getting their truck and

trailer stuck in

the mud (and then being pulled out by the members of the ThrustSSC

team).

On September 4th, 1997, Breedlove and the Spirit of America

crew began testing the car at Black Rock. Breedlove and his team

struggled with

everything from a damaged engine (and a spare engine back in California

that they hadn't even brought with them) to getting their truck and

trailer stuck in

the mud (and then being pulled out by the members of the ThrustSSC

team). Richard Noble had a vision. He wanted to beat the world land speed

record, and he believed he could do it. The record to beat was his own,

set on October

4th, 1983 in Thrust 2, a jet car that was designed by John

Ackroyd, with brakes and wheels that were designed with the help of

Glynne

Bowsher.

Richard Noble had a vision. He wanted to beat the world land speed

record, and he believed he could do it. The record to beat was his own,

set on October

4th, 1983 in Thrust 2, a jet car that was designed by John

Ackroyd, with brakes and wheels that were designed with the help of

Glynne

Bowsher. Glynne Bowsher, who had helped Noble with the design of the Thrust 2,

was happy to be able to contribute to the new project as the mechanical

and structural

designer.

Glynne Bowsher, who had helped Noble with the design of the Thrust 2,

was happy to be able to contribute to the new project as the mechanical

and structural

designer. Arrows are made with weight at the front, so to provide stability, a

forward center of gravity was called for. Concern for the safety of the

driver lead to the

decision to use two jet engines, with one on either side of the driver.

At speed, this would make it easier for the driver to have a feel for

what the car was

doing. As a bonus, the two engines would also provide enough thrust to

overcome tremendous aerodynamic drag and rolling resistance.

Arrows are made with weight at the front, so to provide stability, a

forward center of gravity was called for. Concern for the safety of the

driver lead to the

decision to use two jet engines, with one on either side of the driver.

At speed, this would make it easier for the driver to have a feel for

what the car was

doing. As a bonus, the two engines would also provide enough thrust to

overcome tremendous aerodynamic drag and rolling resistance. Amongst considerable skepticism, a scaled-down version of the car's

proposed wheel layout was built, using an old Austin Mini that belonged

to Bowsher's

brother-in-law.

Amongst considerable skepticism, a scaled-down version of the car's

proposed wheel layout was built, using an old Austin Mini that belonged

to Bowsher's

brother-in-law. Gaining access to a Cray Research 92 computer with Flite aviation design

software enabled them to refine the concept, using computational fluid

dynamics. After

a great deal of work, they were able to predict the car's performance

under a variety of conditions.

Gaining access to a Cray Research 92 computer with Flite aviation design

software enabled them to refine the concept, using computational fluid

dynamics. After

a great deal of work, they were able to predict the car's performance

under a variety of conditions. Noble wisely decided that since this was to be an exceptional race car,

its driver must have some exceptional skills. And the more the project

progressed, the

more it became apparent that he needed to focus on its other aspects:

Noble wisely decided that since this was to be an exceptional race car,

its driver must have some exceptional skills. And the more the project

progressed, the

more it became apparent that he needed to focus on its other aspects: Of all of the contenders, one man came out on top: a British Royal Air Force jet fighter pilot named Andy Green.

Of all of the contenders, one man came out on top: a British Royal Air Force jet fighter pilot named Andy Green. Arrangements were made to borrow the largest airplane in the world, the

Russian Antonov 124 cargo plane. The Antonov would make it possible to

transport the

completed race car, its spare jet engines, spare parts, tools, pit

control station, computers and data acquisition equipment, all of the

required support cars,

trucks, trailers, and ATVs, ultralight aircraft for flying overhead to

check the track and take photographs, a number of big tents to protect

everything, and a

whole lot of fuel.

Arrangements were made to borrow the largest airplane in the world, the

Russian Antonov 124 cargo plane. The Antonov would make it possible to

transport the

completed race car, its spare jet engines, spare parts, tools, pit

control station, computers and data acquisition equipment, all of the

required support cars,

trucks, trailers, and ATVs, ultralight aircraft for flying overhead to

check the track and take photographs, a number of big tents to protect

everything, and a

whole lot of fuel. Special thanks go to Jeremy Davey, the Webmaster of the ThrustSSC Web

site, who took most of the pictures that appear in this article. Until

the team reached

their objective, their site was revised regularly. Jeremy Davey did a

superb job of sharing the excitement and suspense of their adventure

with the rest of the

world.

Special thanks go to Jeremy Davey, the Webmaster of the ThrustSSC Web

site, who took most of the pictures that appear in this article. Until

the team reached

their objective, their site was revised regularly. Jeremy Davey did a

superb job of sharing the excitement and suspense of their adventure

with the rest of the

world. Shown on the right are world land speed record holder Richard Noble

(left) and aerodynamicist Ron Ayers (right), standing beside ThrustSSC

as its construction

was underway.

Shown on the right are world land speed record holder Richard Noble

(left) and aerodynamicist Ron Ayers (right), standing beside ThrustSSC

as its construction

was underway. "We could download the data between runs and check the safety-critical

items like the wheel loads on the desert, the bearing temperatures, et

cetera. We did

this between runs, even when we were breaking records and we had to do

the turnaround within the hour. While we were refueling the car, which

took about twenty

minutes, we could download data that myself, Glynne Bowsher, Jeremy

Bliss and probably Andy Green, the driver, would then check. We knew in

advance what we

wanted to check. We could call up that data and check that the lines

were where we expected them to be on the graphs, and that there was

nothing near to the

limits. If this was so, then we would authorize the next run."

"We could download the data between runs and check the safety-critical

items like the wheel loads on the desert, the bearing temperatures, et

cetera. We did

this between runs, even when we were breaking records and we had to do

the turnaround within the hour. While we were refueling the car, which

took about twenty

minutes, we could download data that myself, Glynne Bowsher, Jeremy

Bliss and probably Andy Green, the driver, would then check. We knew in

advance what we

wanted to check. We could call up that data and check that the lines

were where we expected them to be on the graphs, and that there was

nothing near to the

limits. If this was so, then we would authorize the next run." Jeremy Bliss designed an active rear suspension system to allow the rake

of the car to be adjusted during its runs, very quickly. It worked

quite well.

Jeremy Bliss designed an active rear suspension system to allow the rake

of the car to be adjusted during its runs, very quickly. It worked

quite well. Some think the car looks like a giant hot dog. An article Ayers wrote about the shape of the car contains a story worth sharing:

Some think the car looks like a giant hot dog. An article Ayers wrote about the shape of the car contains a story worth sharing: Then another longtime racing fan became involved. King Hussein of Jordan

provided access to a large area of the Jafr desert, with the full

cooperation of the

Jordanian Army. On two visits a number of test runs were made. The team

spent thousands of hours clearing a course for the car to run on,

battling dust storms

and torrential rain.

Then another longtime racing fan became involved. King Hussein of Jordan

provided access to a large area of the Jafr desert, with the full

cooperation of the

Jordanian Army. On two visits a number of test runs were made. The team

spent thousands of hours clearing a course for the car to run on,

battling dust storms

and torrential rain. After the final adjustments and improvements were made to the car,

ThrustSSC was pronounced ready for its mission. It was time to make

history.

After the final adjustments and improvements were made to the car,

ThrustSSC was pronounced ready for its mission. It was time to make

history. The desert has been used as a firing range, and is littered with

thousands of artillery shells. The entire course had to be inspected and

cleared of anything

that might cause damage to the race car's engines or wheels.

The desert has been used as a firing range, and is littered with

thousands of artillery shells. The entire course had to be inspected and

cleared of anything

that might cause damage to the race car's engines or wheels.

The unaltered photograph on the right is one of a series of pictures taken by

The unaltered photograph on the right is one of a series of pictures taken by

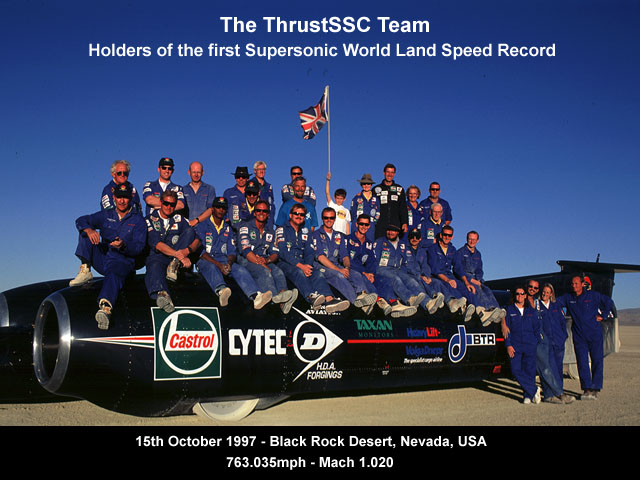

On Wednesday, October 15th, 1997, the ThrustSSC team made two more runs. The first, the car's 65th run, was timed at 759.333 miles per

hour, which is Mach 1.015. The all-important backup run was successfully made within the hour, at 766.609 miles per hour.

On Wednesday, October 15th, 1997, the ThrustSSC team made two more runs. The first, the car's 65th run, was timed at 759.333 miles per

hour, which is Mach 1.015. The all-important backup run was successfully made within the hour, at 766.609 miles per hour.